manual handling training course online

Manual Handling Training Course Online: A Comprehensive Guide

Welcome! This guide offers a comprehensive overview of online manual handling training courses. It emphasizes the importance of safe practices‚ legal duties for employers and employees‚ and effective techniques for workplace safety.

Manual handling encompasses a wide range of physical activities involving the movement of loads. These tasks are common across various work environments. It is crucial to understand the risks associated with incorrect handling techniques. Poor practices are a significant cause of workplace injuries and long-term health issues. Effective manual handling minimizes strain on the body. It promotes alternative methods‚ and emphasizes ergonomic behaviors. Training in safe manual handling practices is essential for preventing injuries. It ensures compliance with health and safety regulations. This understanding reduces the risk of injuries at work‚ mitigating the costs of absence and fostering a safer working environment.

Why Manual Handling Training is Important

Manual handling training is crucial for preventing workplace injuries. It ensures employees understand safe lifting techniques and ergonomic principles. It minimizes risks‚ and promotes a healthier‚ safer work environment.

Legal Responsibilities for Employers and Employees

Employers are legally obligated to provide manual handling training to all staff involved in manual handling operations. This training must cover safe techniques and risk assessment. The goal is compliance with health and safety regulations‚ reducing potential injuries; Employees also have a legal duty to follow safe practices. They should use learned techniques and report hazards. Both employers and employees must be aware of their responsibilities. Compliance minimizes risks and contributes to a safer working environment. Organizations should ensure regular refresher training. This updates knowledge on regulations and reinforces safe manual handling practices. Proper training helps prevent accidents and legal liabilities.

Reducing Workplace Injuries and Costs

Manual handling training significantly reduces workplace injuries by promoting safe lifting and movement techniques. Proper training equips employees to identify and mitigate potential hazards. Fewer injuries translate directly into lower costs for businesses. These cost savings include reduced compensation claims‚ decreased absenteeism‚ and improved productivity. Investing in training demonstrates a commitment to employee well-being. A safer work environment fosters higher morale and job satisfaction. Effective training programs emphasize ergonomic behaviors. They promote alternative methods to reduce physical strain. Implementing these strategies results in a healthier‚ more efficient workforce and substantial financial benefits. Regular training updates are essential for sustained injury prevention.

What Does Manual Handling Involve?

Manual handling encompasses moving heavy loads in any physical work environment. This includes using the body or mechanical aids‚ with careful planning to prevent injuries. Proper risk assessments are vital.

Minimizing Force and Unexpected Movements

Good manual handling practices involve minimizing high or sudden force exertion to reduce strain and prevent injuries. Avoiding unexpected movements is crucial‚ ensuring that all actions are controlled and deliberate. Sustained force should always be kept at safe levels through meticulous planning and risk assessments. Proper lifting techniques‚ ergonomic behaviors‚ and alternative methods play a significant role in minimizing strain on the body.

Understanding common injury causes and the long-term health damages from poor techniques is vital. This approach promotes a safer work environment by prioritizing controlled‚ predictable actions and reducing potential hazards associated with force.

Risk Assessment and Control Measures

Effective manual handling necessitates thorough risk assessments to identify potential hazards associated with lifting and moving loads. Proper planning and risk assessment implementation are key to good manual handling practices. Control measures should minimize high or sudden force‚ prevent unexpected movements‚ and ensure sustained force remains at safe levels.

Organisations are legally required to ensure all employees are trained in risk assessment and control. These measures involve evaluating tasks‚ loads‚ environment‚ and individual capabilities to implement appropriate safety protocols. Regularly updating these assessments ensures continued relevance and effectiveness in preventing workplace injuries related to manual handling.

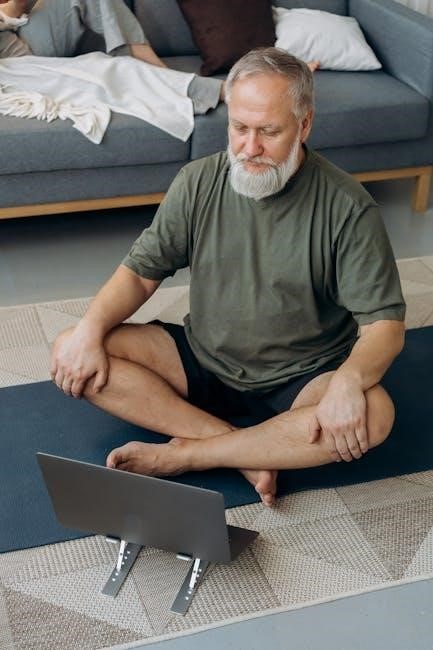

Online Manual Handling Training: Convenience and Accessibility

Online manual handling training offers unmatched convenience. Complete courses anytime‚ anywhere using your phone‚ tablet‚ or computer. Get certified quickly and efficiently‚ fitting training into your schedule seamlessly.

Completing Training via Phone‚ Tablet‚ or Computer

Our RoSPA Assured and CPD Certified Manual Handling Training course is designed for accessibility. The online format allows you to complete the training using a phone‚ tablet‚ or laptop/desktop computer. This flexibility means you can complete your manual handling training instantly and download your certificate immediately. The course delivery and testing are online‚ giving you the freedom to choose when and where you train. This ensures that you can fit the training around your existing commitments‚ making it convenient and efficient to gain essential manual handling skills‚ ensuring compliance and workplace safety.

Course Content and Key Principles

This course comprehensively overviews safe object handling‚ emphasizing its significance for everyday health. Key principles include understanding and applying LITE and TILE‚ ensuring correct manual handling techniques are followed.

Safe Lifting Techniques (LITE and TILE)

Safe lifting techniques are vital for preventing injuries during manual handling. The LITE acronym focuses on Load‚ Individual‚ Task‚ and Environment. Analyzing the Load involves assessing its weight and stability. Understanding the Individual’s capabilities is crucial. Evaluating the Task includes considering movements and distances. Examining the Environment identifies potential hazards.

The TILE acronym considers Task‚ Individual‚ Load‚ and Environment‚ offering a similar framework. Proper application of LITE and TILE helps minimize high or sudden force‚ prevents unexpected movements‚ and ensures sustained force remains at safe levels. Implementing these techniques effectively reduces workplace injuries.

Refresher Training: Maintaining Safety Standards

Refresher training is crucial for reinforcing key principles and updating knowledge on regulations. Regular updates ensure safe manual handling practices‚ contributing to a safer working environment and preventing workplace injuries.

Updating Knowledge on Regulations and Practices

Staying current with regulations and best practices is vital in manual handling. Refresher courses are designed to update participants on any relevant changes‚ reinforcing key principles for safe practices. Regular training ensures a safe working environment and prevents workplace injuries by controlling high force‚ preventing unexpected movements‚ and sustaining safe force levels. Organizations are legally required to ensure all employees are trained and their knowledge regularly updated. Refresher courses are essential for maintaining competency and reducing the risks associated with manual handling tasks. These courses help to avoid injuries and associated costs.

Certification and Assessment

Certification is often provided upon successful completion of the course. Assessments ensure understanding‚ and instant feedback is typically given. Retakes are often available at no extra cost to achieve passing mark.

Online Assessment and Instant Feedback

Online manual handling courses generally include an assessment component to verify understanding of the training material. Candidates usually face multiple-choice questions‚ randomly chosen from a pool‚ requiring a minimum correct answer count to pass. Instant feedback is provided after submission‚ clarifying pass or fail status. Retakes are often available at no extra cost‚ ensuring learners master safe manual handling principles. Completion signifies understanding of hazard identification and injury prevention. The goal is to reduce workplace injury risk. A certificate may be offered upon successful completion‚ demonstrating competency. The assessment evaluates knowledge of safe lifting and ergonomic behavior‚ promoting safer workplaces and cost-effective compliance.

Cost and Duration of Online Courses

Online manual handling training costs vary based on delivery method and location. Duration depends on individual skill level and course content. Online options offer flexibility‚ impacting both price and completion time.

Factors Affecting Course Costs

Several factors influence the cost of online manual handling courses. The provider’s reputation‚ accreditation (e.g.‚ RoSPA‚ IOSH)‚ and the inclusion of practical assessments impact pricing. Courses with video uploads or live Zoom sessions may be more expensive. Content depth‚ covering LITE and TILE techniques‚ and whether the course is nationally recognized also affect the cost.

Bundled courses or those offering refresher training might have different pricing structures. Always compare features like instant certificate download‚ access duration‚ and the availability of support to determine the best value. Finally‚ bulk discounts can lower per-person costs.